| Payment Type: | L/C,T/T,D/P,Money Gram,Western Union |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Min. Order: | 1 Piece/Pieces |

| Delivery Time: | 8 Days |

Basic Info

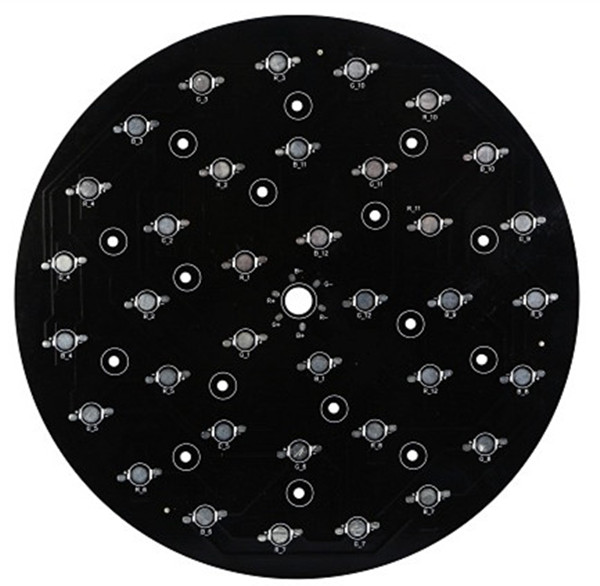

Model No.: CW-017

Structure: Metal Base Rigid PCB

Flame Retardant Properties: V0

Base Material: Aluminum

Insulation Materials: Metal Composite Materials

Additional Info

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 10000sqm/month

Certificate: ISO9001, ISO14001, UL, IATF16949

Product Description

The circuit layer (ie, copper foil) is usually etched to form a printed circuit, so that the various components of the component are connected to each other. In general, the circuit layer is required to have a large current carrying capacity, so that a thick copper foil should be used, and the thickness is generally 35 μm. 280μm; thermal conductive insulation layer is the core technology of aluminum substrate. It is generally composed of special polymer filled with special ceramics. It has small thermal resistance, excellent viscoelasticity, anti-heat aging ability, and can withstand mechanical and thermal stress.

The thermal conductive insulating layer of the high-performance aluminum substrate uses this technology to have excellent thermal conductivity and high-insulation electrical insulation properties; the metal base layer is a supporting member of the aluminum substrate, and is required to have high thermal conductivity, generally aluminum plate. Copper plates (where copper plates provide better thermal conductivity) can also be used, which are suitable for conventional machining such as drilling, punching and cutting.

Specifications:

Material: Aluminium

Layer: 1L

Copper thickness: 1OZ

Board thickness: 1.0mm

Surface Finishing: HASL-LF

Solder mask color: Black

Silkscreen color: White

Thermal Conductivity: 1.0W/M.K

________________________________________________________________________________________________________________________________________________________

Aluminum circuit boards is a metal-based copper clad plate with good heat dissipation function. Generally, the single layer is composed of three-layer structure, which is a circuit layer (copper foil), an insulating layer and a metal base layer. Also used for high tech use is designed as double layers, the structure is circuit layer, insulation layer, aluminum base, insulation layer, circuit layer. A very small number of applications are multi-layer boards, which can be made of ordinary multi-layer boards combined with an insulating layer and an aluminum base.

Aluminum PCB characteristics

● Surface Mount Technology (SMT);

● Extremely efficient treatment of thermal diffusion in circuit design;

● Reduce product operating temperature, increase product power density and reliability, and extend product life;

● Reduce product size and reduce hardware and assembly costs;

● Replace the fragile ceramic substrate for better mechanical durability.

Aluminum PCB use:

● Audio equipment

Input, output amplifiers, balanced amplifiers, audio amplifiers, preamplifiers, power amplifiers, etc.

● Power supply equipment

Switching regulator, DC/AC converter, SW regulator, etc.

● Communication electronic equipment

High frequency amplifier, filtering appliance, reporting circuit, etc.

● Office automation equipment

Motor drive, etc.

● Automotive

Electronic regulator, ligniter, power controller, etc.

● Computer

CPU board, floppy disk drive, power supply unit, etc.

● Power module

Inverter, solid relay, rectifier bridge and so on.

● LED lighting

With the promotion of energy-saving lamps, various energy-saving and beautiful LED lamps have been well received by the market, and aluminum PCB used for LED lamps have also begun to be applied on a large scale.

__________________________________________________________________________________________________________________________________________

1, About the factory--More than 15 years industry experience: Self-built factory, 15 years of focus on circuit board manufacturing.

☆ Flip Aluminium PCB: The share of Aluminum industry more than 45%, service and quality have won the praise of customers.

☆ Advanced equipment: PVC plating line, CNC V-CUT machine, Dongtai high speed drilling machine, high speed flying probe testing machine, microscope, copper foil tensile tester, ion pollution degree detector.

2, Top technical team - fast delivery, professional service

☆ 50 professional and technical people with more than 10 years of PCB experience have rich experience in various industry standards and process quality requirements.

☆ Provide after-sales technical support, quickly respond to bad feedback, solve customer's difficult problems

3, Certifications - UL, IO9001:2015, ISO14001:2015, IATF16949

☆ All products undergo strict SGS testing and meet ROHS requirements

☆ Implement TQM quality management and 6σ management mode, continuous improvement, good rate 99%

☆ Quality control seniors are skilled in IATF16949, QS9000 requirements,and have their internal auditor qualification certificate

4.Work with well-known companies - trustworthy PCB manufacturers

☆ Over the years, has business contacts with many well-known companies such as BYD, Huawei, Schneider, and Siemens etc., and has maintained long-term supply relationships with these industry benchmarking companies.

☆ The products are exported to Europe, America, Japan, Middle East, Philippines and other overseas markets, and are well received and trusted by customers.

CONTACT US

Chuangying Electronics Co.,Ltd

Contact Person: Gracie Cai

Phone:86-755-29493085

Fax:

Address: No.15 Gonghe Chuangye road, Xixiang Street,Shenzhen,Guangdong