| Payment Type: | L/C,T/T,D/P,Money Gram,Western Union |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Min. Order: | 1 Piece/Pieces |

| Delivery Time: | 8 Days |

Basic Info

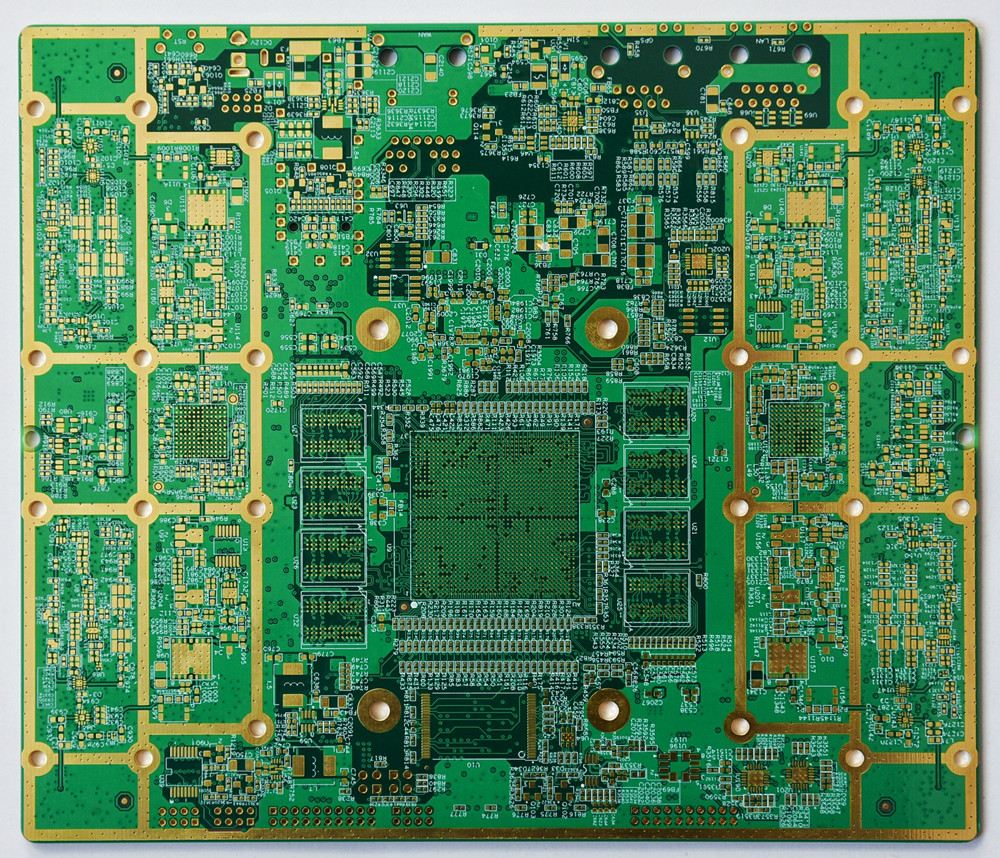

Model No.: CW-245

Structure: Multilayer Rigid PCB

Dielectric: FR-4

Application: Consumer Electronics

Flame Retardant Properties: V0

Additional Info

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 10000sqm/month

Certificate: ISO9001, ISO14001, UL, IATF16949

Product Description

Traceability: Products require strict process records and product traceability, and some large medical terminals require assurance 10-year traceability of PCB processing records.

Medical pcb board requires different processing and fire protection requirements. The ordinary PCB process is different when processing tin spray and cleaning the board. Under the premise of adopting technological measures and ensuring quality and safety, it can be used for repairs with discretion.

The BGA package's I / O terminals are distributed under the package in a circular or columnar solder joint in an array. The advantage of BGA technology is that although the number of I / O pins has increased, the pin pitch has not decreased but increased. Improved assembly yield; although its power consumption increases, the BGA can be soldered using a controlled collapse chip method, which can improve its electrical and thermal performance; thickness and weight are reduced compared to previous packaging technologies; parasitic parameters (large current When the amplitude changes, the output voltage disturbance is reduced), the signal transmission delay is small, and the use frequency is greatly increased; assembly can be coplanar welding, and the reliability is high.

Specifications:

Material: FR4

Layer: 8L

Copper thickness: 1OZ

Board thickness: 1.6mm

Surface Finishing: ENIG

Solder mask color: Green

Silkscreen color: White

Describe:

____________________________________________________________________________________

Printed circuit boards abbreviation as PCB. A conductive pattern which is formed on a dielectric material in a predetermined design to form a printed circuit, a printed component, or a combination of the two is generally referred to as a printed circuit. And a conductive pattern that provides electrical connection between components on an insulating substrate, called printed circuits.

PCB characteristics

● High density. For decades, the high density of printed boards has grown with the increased integration of integrated circuits and advances in mounting technology.

● High reliability. Through a series of inspections, tests and aging tests, the PCB can be reliably operated for a long period of time (usually 20 years).

● Designability. For the various performances of PCB (electrical, physical, chemical, mechanical, etc.), the design of printed boards can be realized through design standardization and standardization, with short time and high efficiency.

● Productivity. With modern management, it can carry out standardization, scale (quantity), automation and other production to ensure product quality consistency.

● Testability. Established relatively complete test methods, test standards, various test equipment and instruments to detect and identify PCB product qualification and service life.

● Assemblyability. PCB products not only facilitate the standardized assembly of various components, but also can be automated, large-scale mass production. At the same time, the PCB and various component assembly components can be assembled to form larger components and systems up to the complete machine.

● Maintainability. Since PCB products and various component assembly components are produced in a standardized design and scale, these components are also standardized. Therefore, once the system fails, it can be replaced quickly, conveniently and flexibly, and the system can be quickly restored. Of course, you can say more about it. Such as miniaturization and weight reduction of the system, high-speed signal transmission, etc.

____________________________________________________________________________________

1, About the factory--More than 15 years industry experience: Self-built factory, 15 years of focus on circuit board manufacturing.

☆ Flip Aluminium PCB: The share of Aluminum industry more than 45%, service and quality have won the praise of customers.

☆ Advanced equipment: PVC plating line, CNC V-CUT machine, Dongtai high speed drilling machine, high speed flying probe testing machine, microscope, copper foil tensile tester, ion pollution degree detector.

2, Top technical team - fast delivery, professional service

☆ 50 professional and technical people with more than 10 years of PCB experience have rich experience in various industry standards and process quality requirements.

☆ Provide after-sales technical support, quickly respond to bad feedback, solve customer's difficult problems

3, Certifications - UL, IO9001:2015, ISO14001:2015, IATF16949

☆ All products undergo strict SGS testing and meet ROHS requirements

☆ Implement TQM quality management and 6σ management mode, continuous improvement, good rate 99%

☆ Quality control seniors are skilled in IATF16949, QS9000 requirements,and have their internal auditor qualification certificate

4.Work with well-known companies - trustworthy PCB manufacturers

☆ Over the years, has business contacts with many well-known companies such as BYD, Huawei, Schneider, and Siemens etc., and has maintained long-term supply relationships with these industry benchmarking companies.

☆ The products are exported to Europe, America, Japan, Middle East, Philippines and other overseas markets, and are well received and trusted by customers.

CONTACT US

Chuangying Electronics Co.,Ltd

Contact Person: Gracie Cai

Phone:86-755-29493085

Fax:

Address: No.15 Gonghe Chuangye road, Xixiang Street,Shenzhen,Guangdong